Small is Beautiful

Your organization is made up of tiny little decisions made every day by thousands of individuals. That's it! Seriously that’s what makes up your company. Unless you’re some kind of futuristic company with no human employees or customers, that’s how your company realizes its accomplishments. Those small decisions add up to your organization posting a profit, loss, or any number at all.

In management consulting, we obsess with the categories of People, Process, and Technology for making organizational improvements. But those pillars of organizational improvement seem to leave employees in a robotic malaise.

Here’s a Small Case Study…

A few years back, we vetted a process at an investment bank that was resulting in massively negative customer feedback. Customers were going onto social media to complain that their investment bank wasn’t letting them get their money out. Obviously not a good message.

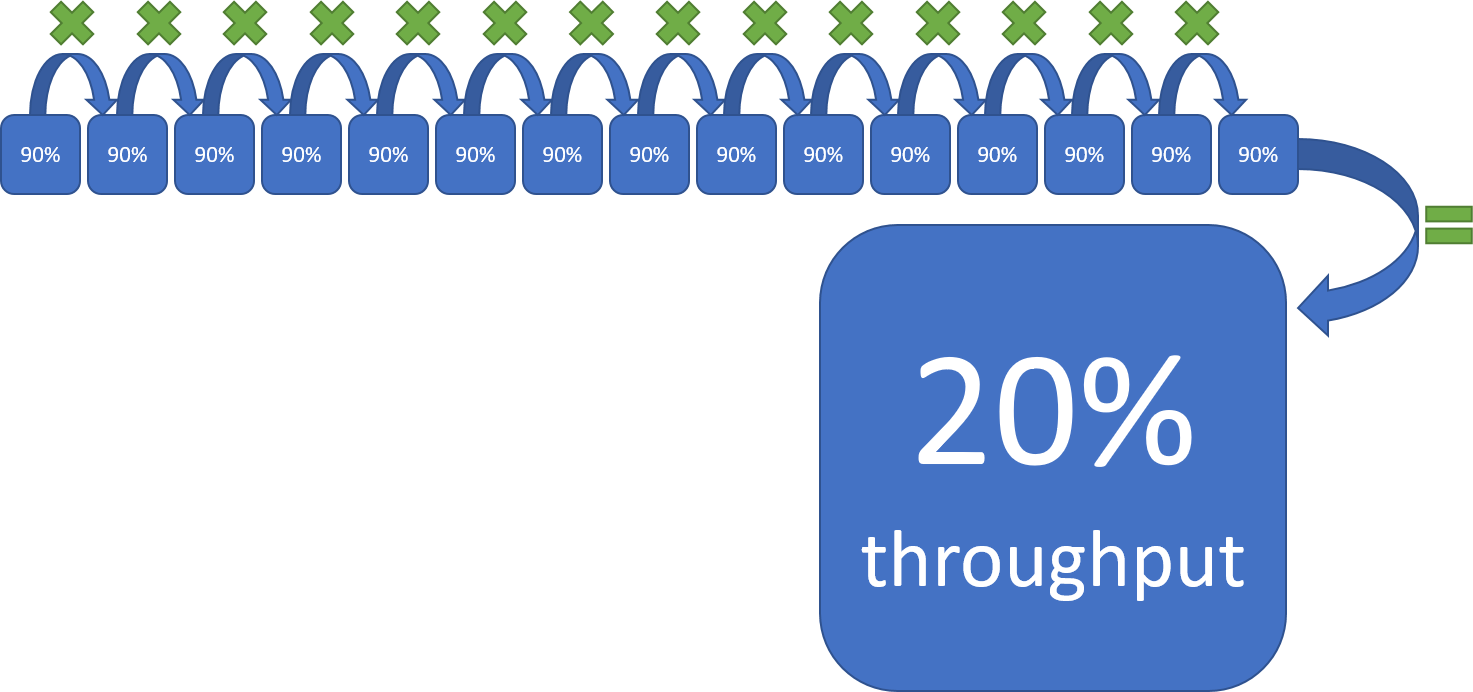

As we traversed the long-standing processes we found it took 15 distinct steps, internally, to get a retirement account closed. As you may already know, to determine the downstream effects of a process, we multiply their probabilities of success. So let’s imagine that every step in the process had a 90% success rate. That sounds pretty good, right? Well, where would that lead the end customer?

20%! That means that 20% of the time, the customer would actually get their money without a hitch. Otherwise, it would get hung up in a nasty and frankly unnecessary process.

Why was the organization so inept? Was the process broken and dumb headed… yes! But why is it that the people couldn’t come up with an effective way of fixing the obvious?

When we interviewed the people in charge of the process their answer was “this was a process that was given to me by my predecessor”, or “this step satisfies a legal requirement.” (which nobody could identify) Everybody knew the process was broken. The source of the problem started staring us in the face… Culture. The culture of the organization was not one that required the organization to be customer centric. They were the biggest, the best, and management knew it. So they didn’t have to focus on improvement. This smug management culture trickled down into the organization, and perpetuated a feeling of indifference about customers. After all, “who else would they go to?”

Those tiny decisions that your organization makes, are framed by the culture in your company. If I were to select between excellence in People, Process, Technology, or Culture I would pick Culture. Culture will be at the foundation of… what people you hire, what technologies you adopt, and whether your processes improve.

The more influential your culture, the less you’ll have to create process controls and other expensive gate keeping measures to achieve success.

So Why Does Intricity, a Company That Lives and Breathes Data, Care so Much About Culture?

For many companies, they feel they can check off the culture box by hanging some inspirational slogan in an HR person’s cubicle. Culture isn’t some kind of “feel good” way of doing business, rather it’s a strategy to effect how decisions get made by individuals.

So, it’s about helping people align their decisions with the culture of the organization they work with. Intricity lives in the world of enabling decisions. We are a guide at the crossroad of making better decisions. This is because we build the systems that enable decisions to be made on a regular basis. You could say we’re specialists in automating the manufacturing of data into actionable information.

Because we live at this crossroad, we’re smack dab in the middle of organizational culture. And when companies come to us with problems related to their data, the cultural issues come in tow.

Because we live at this crossroad, we’re smack dab in the middle of organizational culture. And when companies come to us with problems related to their data, the cultural issues come in tow.

Engineered Culture

Culture should not be something that derives from the organics of your company, like the tail wagging the dog. Rather culture needs to be carefully engineered to suit the outcome you want. To do that, your organization is going to need to master a new industry. Because believe it or not, your organization is not just in the industry analysts say you’re in. I’ve said this to various companies and I get an odd look from them. Just recently I said it to a manufacturing company, and explained, “you manufacture computer chips, AND you manufacture data into information.” Every company over 100 Million dollars is in that boat. You simply can’t run your company from gut feel after a certain point. So, if you never become proficient at manufacturing data into information, you will not succeed in your primary purpose. Thus data-to-information manufacturing needs to have a place in your company’s culture. Because it is the very mechanics for effecting the behaviors you want to see.

Let Me Give You An Example:

Several years ago, we were consulting at a multi-billion-dollar fashion retailer. They had invested millions of dollars in a new training program for their floor sales staff. This new innovative training program had upper management very excited, and they were looking forward to a big spike in their sales. Month 1 went by with little change in sales, which was written off as a fluke. After the second Quarter went by with crickets chirping, management members had their tails between their legs. All sorts of blame started swirling around.

What was missing from the equation was information to the sales staff. Plenty of information was coming back to management. But the sales staff had no personal daily engagement into the desired outcome. One of our architects came up with a carefully crafted dashboard called the “Red Line”, which was a personal performance tracker for the sales staff. The data points were painstakingly assembled to marry up with the sales tactics from the training program. Each sales rep on the floor could see how they were performing compared to their peers, and they could see that the sales tactics used in the training were contributing to performance increases.

That dashboard established a cultural change which completely turned the retailers sales training program into a gigantic success. They booked several record quarters for the company, and the CEO became a regular on the business news channels.

Data-to-Information Manufacturing

Data-to-Information Manufacturing

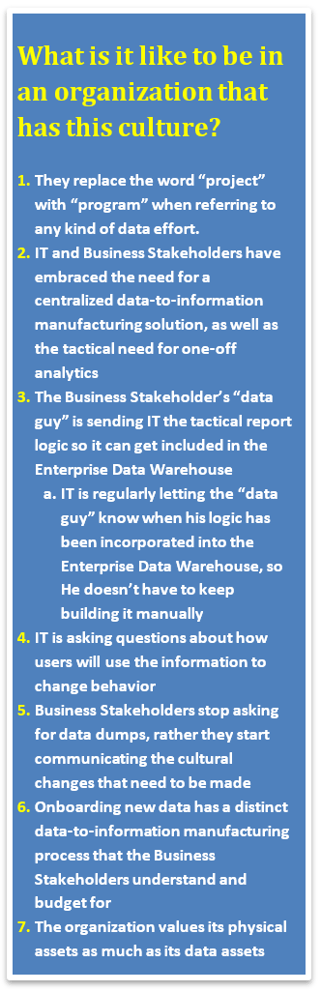

The cultural change in data-to-information manufacturing is on multiple levels:

From the level of raw data, it’s a recognition from Business Stakeholders that it’s just like a raw material. Raw materials by their nature are not ready to consume. To get raw data ready to consume we have to put work into it. That cultural change of mind is huge.

The behavior of most Business Managers is to get their “data guy” to start banging out Excel workbooks until they have the information they need. But what that Business Manager might not know is that there are 20 other Business Managers doing the exact same thing. Now try to make a strategic decision… Bring those 20 versions of the truth to a CFO or CEO and ask them to make a decision on whether to lay off 30% of the company.

By valuing the manufacturing of raw data into actionable information, we start getting out of the hamster wheel of creating data silos. The management starts to see that funding such an effort is simply part of the function of being a large business and not some kind of “project”.

From the level of Actionable Information, IT begins to see that the data-to-information manufacturing end game, is a cultural one. Information should drive a culture that the Business Stakeholders want to perpetuate. (Like our retail case study) The entire effort of manufacturing information is to enable the Business to define their culture and ensure its sustainability. This realization is also a big “ah ha” moment for IT. Business requirements become a lot less about gathering data and more about the behaviors the organization wants to perpetuate.

Creating a New Culture

First and foremost, there’s no “app for that.” Culture is slow and requires serious patience. Sometimes it requires grand gestures to kick them off. For example, when Ford made its iconic tipping point in a single gesture by the CEO, Alan Mulally:

“Mulally introduced a “traffic light” system to weekly BPRs in which executives indicated progress on key initiatives as green, yellow, or red. After four meetings in which all programs were labelled green, Mulally confronted his team, “We are going to lose $18 billion this year, so is there anything that’s not going well?” His question was met with stony silence.

The following week, North American President Mark Fields showed a red indicator that a new  vehicle launch would be delayed. Other executives assumed Fields would be fired over the bad news. Instead, Mulally began clapping and said, “Mark, that is great visibility.” He asked the group, “What can we do to help Mark out?” As he frequently told his leaders, “You have a problem; you are not the problem.”

vehicle launch would be delayed. Other executives assumed Fields would be fired over the bad news. Instead, Mulally began clapping and said, “Mark, that is great visibility.” He asked the group, “What can we do to help Mark out?” As he frequently told his leaders, “You have a problem; you are not the problem.”

http://www.huffingtonpost.com/bill-george/bringing-out-our-worst-or_b_9527626.html

Building a new culture usually requires an outsider like Mulally. The organization needs the vision of somebody that has tread in the shoes of success, and understands what it looks like. This is because things are going to happen to challenge the new norm which will require the new agent of culture to show the “how”. This is where having consultants starts making sense, and is the realm that Intricity plays in. It’s in the coupling of the Intricity team members together with the Business & IT Stakeholders to guide the “art of the possible”. Intricity joins your organization at the hip by providing resources at multiple levels to instill new behaviors and belief systems.

to guide the “art of the possible”. Intricity joins your organization at the hip by providing resources at multiple levels to instill new behaviors and belief systems.

Usually we start these engagements with a Current State Assessment, and a visual map of where we think the future state should be. This acts as a good place to help the organization determine the budgets which the new culture will be built on, and the right people to attach at hip with the Intricity team members.

To engage with Intricity on a Current State Assessment I recommend you reach out to us and talk with our specialists. We can help you engineer the culture your organization is seeking to drive, and support that new culture with the data-to-information manufacturing process, which will make it sustainable over the long run.

Who is Intricity?

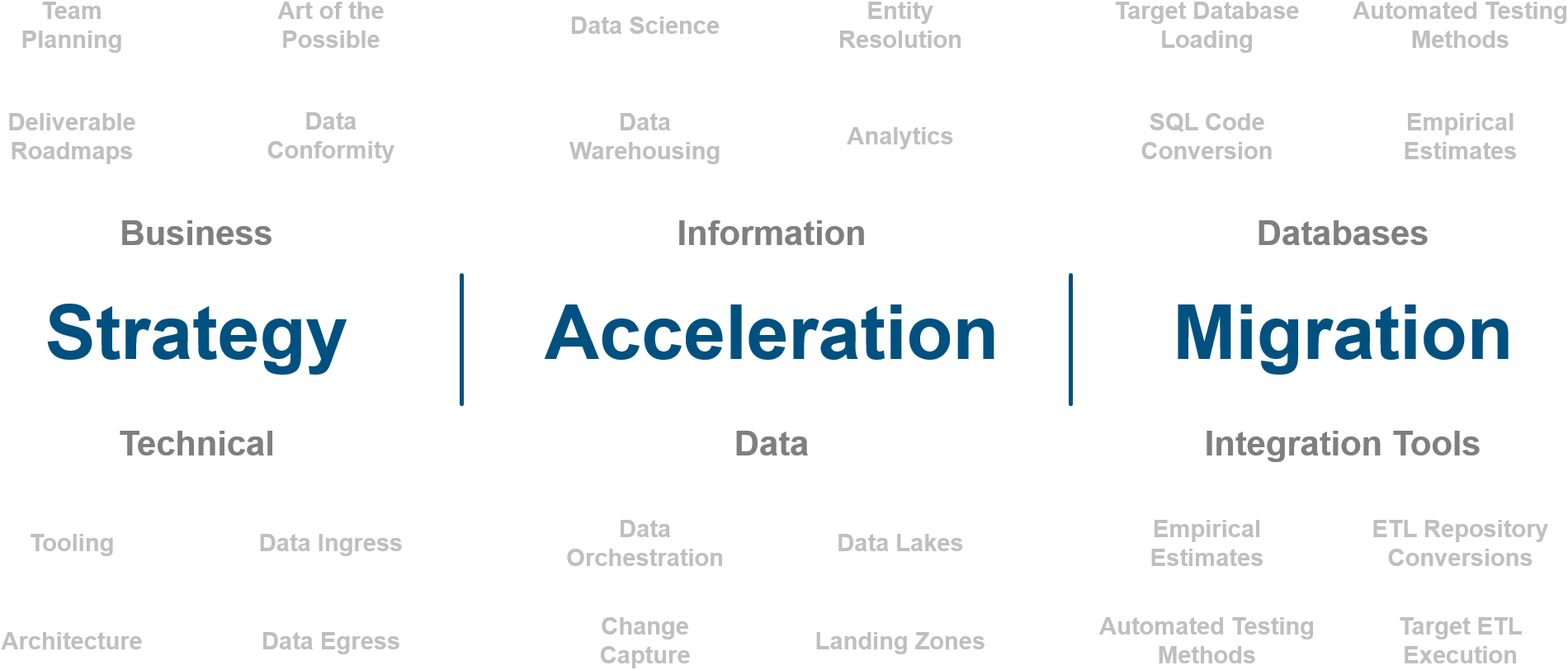

Intricity is a specialized selection of over 100 Data Management Professionals, with offices located across the USA and Headquarters in New York City. Our team of experts has implemented in a variety of Industries including, Healthcare, Insurance, Manufacturing, Financial Services, Media, Pharmaceutical, Retail, and others. Intricity is uniquely positioned as a partner to the business that deeply understands what makes the data tick. This joint knowledge and acumen has positioned Intricity to beat out its Big 4 competitors time and time again. Intricity’s area of expertise spans the entirety of the information lifecycle. This means when you’re problem involves data; Intricity will be a trusted partner. Intricity's services cover a broad range of data-to-information engineering needs:

What Makes Intricity Different?

While Intricity conducts highly intricate and complex data management projects, Intricity is first a foremost a Business User Centric consulting company. Our internal slogan is to Simplify Complexity. This means that we take complex data management challenges and not only make them understandable to the business but also make them easier to operate. Intricity does this through using tools and techniques that are familiar to business people but adapted for IT content.

Thought Leadership

Intricity authors a highly sought after Data Management Video Series targeted towards Business Stakeholders at https://www.intricity.com/videos. These videos are used in universities across the world. Here is a small set of universities leveraging Intricity’s videos as a teaching tool:

Talk With a Specialist

If you would like to talk with an Intricity Specialist about your particular scenario, don’t hesitate to reach out to us. You can write us an email: specialist@intricity.com

(C) 2023 by Intricity, LLC

This content is the sole property of Intricity LLC. No reproduction can be made without Intricity's explicit consent.

Intricity, LLC. 244 Fifth Avenue Suite 2026 New York, NY 10001

Phone: 212.461.1100 • Fax: 212.461.1110 • Website: www.intricity.com