Building a dynamically scalable infrastructure to support Internet of Things (IoT) data feeds.

About Customer: World Leading Manufacturer of Pumps and Pump Sensors

This manufacturer is among the most widely recognized and respected brands in the global pump industry, serving customers in the oil and gas, mining, power generation, chemical, pulp and paper, and general industrial markets. This organization was not just a leader in their space but also laser-focused on deploying smart technologies on their devices. To respect the unanimity of our customer and their solution, we’ll refer to this organization as “CLIENT”.

About Intricity

Intricity is a team of specialized Data Management, Data Warehousing, and Business Intelligence experts. The team members at Intricity have been handpicked over the course of 20 years, and represent the top talent globally in data-oriented disciplines.

Case Study

CLIENT has engineered a pump sensor which has been broadly adopted across the manufacturing industry to measure both temperature and vibration. These sensors helped engineers determine whether pumps were nearing their service capacity and aid in diagnosing problems. The sensor was designed to work on any pump whether that pump came from the CLIENT’s product lines or not. The mechanism for gathering the data off the pump sensors was an Android app which the Vibration Engineer would use to connect to the sensors' Short-Range Bluetooth transmitter. With many manufacturing plants housing thousands of pumps, it's easy to see how daunting this regular task of data gathering could be for CLIENT’s customers.

CLIENT had developed an app for Vibration Engineers to use in drawing data from the pump sensors but it lacked a legitimate data backbone to support the IoT data coming off the pumps. Early attempts to centralize the data feeds leveraged a traditional IT architecture which resulted in an inability to scale to CLIENT’s broad customer base. Their data backbone had a broad range of data needs like replication, scalability, security, aggregation, interactivity, and future-proofing. CLIENT wanted to accomplish all those needs while in parallel avoiding a giant IT footprint to manage all those functions.

The drive to implement a centralized IoT backbone stemmed not only from the time savings that CLIENT could offer their customers but also the ability to leverage the data as another service that could be sold back to its customers in the form of valuable plant analytics. Additionally, this information could guide the sales organization within CLIENT to enable effective targeting of new pump sales based on hard data coming from the plants themselves. Thereby ensuring they were well-positioned to sell the replacement pumps.

Thus the IoT opportunity for CLIENT was satisfying both an Efficiency Innovation and a Disruptive Innovation.

While CLIENT understood the benefits of creating a centralized IoT data backbone, they realized based on their failed attempts earlier that they would need to work with an organization that had experience working with such complexity.

Solution

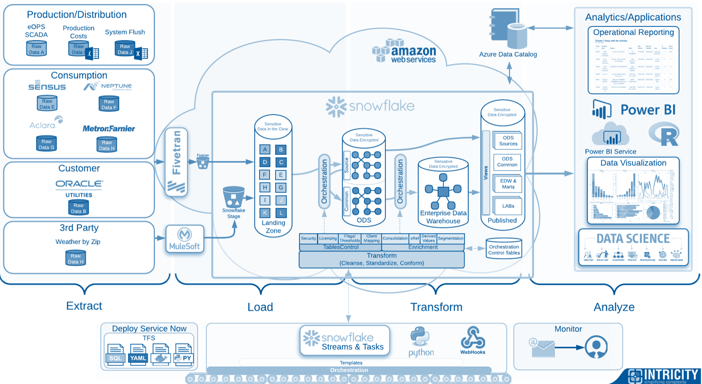

CLIENT reached out to Intricity to evaluate the current IoT backbone and come up with a game plan for how to realize its end goals. After a short technical assessment Intricity developed a Logical Solution Architecture that represented the future state process for turning raw data into consumable information. This artifact acted as a springboard to envision the future state serviceability of the data to the various information needs down the line.

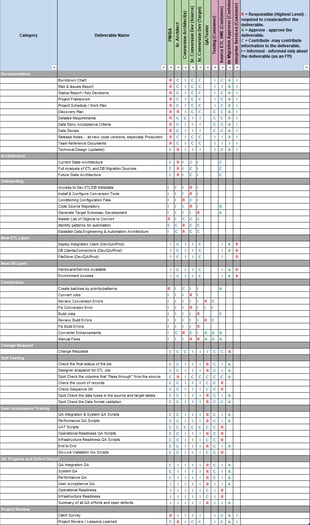

Using the Logical Solution Architecture Intricity created a development roadmap which was accompanied by a RACI diagram. (Responsible, Accountable, Consulted and Informed) This enabled CLIENT’s team members involved with the project to understand their roles and prepare the organization for the development of their IoT data backbone.

Following the deployment of the RACI, Intricity began deploying the technical landscape defined in the Logical Solution Architecture. This included leveraging Machine-to-Machine Connectivity Protocols for acquiring the data and landing that data into Amazon AWS as the foundation of the architecture.

Within the Amazon AWS architecture, Intricity deployed AWS Lambda to convert data so it could be staged on Amazon S3 as well as develop a Vibration Engineering Application using Amazon’s Elastic Beanstalk for scalable application processing and AWS Cognito to manage its security.

Intricity also leveraged a scalability automation solution which allowed the end solution to elastically scale on demand further relieving the burden of IT’s operational oversight of the solution.

In addition to leveraging a full cloud serverless solution, Intricity also helped CLIENT adopt the latest agile development best practices. In addition to helping the organization adopt technologies that speed up the development process like Slack and Git Hub.

In the end, CLIENT was up and running with an application that provided the organization with a fully scalable back end which provided options for ingesting data either directly from the Bluetooth Pump Sensors or acquiring the data from the Engineers Android Tablets which provided a global view of pump performance and delivered a meaningful interface for Vibration Engineers to evaluate the overall health of the plant in a consolidated view. CLIENT has a foundation for which they can run machine learning on the vibration data and sell findings through a data subscription model.

Call to Action

To schedule time to discuss your IoT landscape with an Intricity specialist, fill out the form below.

Who is Intricity?

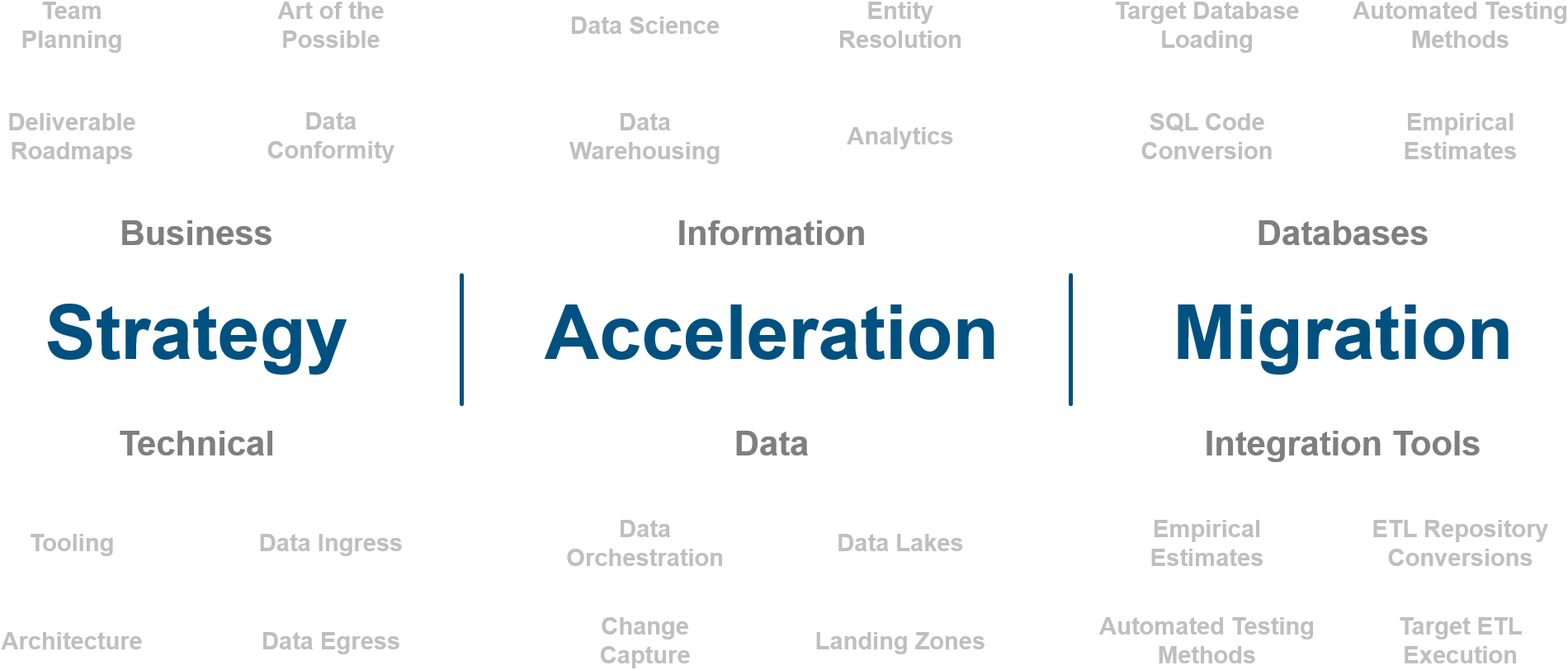

Intricity is a specialized selection of over 100 Data Management Professionals, with offices located across the USA and Headquarters in New York City. Our team of experts has implemented in a variety of Industries including, Healthcare, Insurance, Manufacturing, Financial Services, Media, Pharmaceutical, Retail, and others. Intricity is uniquely positioned as a partner to the business that deeply understands what makes the data tick. This joint knowledge and acumen has positioned Intricity to beat out its Big 4 competitors time and time again. Intricity’s area of expertise spans the entirety of the information lifecycle. This means when you’re problem involves data; Intricity will be a trusted partner. Intricity's services cover a broad range of data-to-information engineering needs:

What Makes Intricity Different?

While Intricity conducts highly intricate and complex data management projects, Intricity is first a foremost a Business User Centric consulting company. Our internal slogan is to Simplify Complexity. This means that we take complex data management challenges and not only make them understandable to the business but also make them easier to operate. Intricity does this through using tools and techniques that are familiar to business people but adapted for IT content.

Thought Leadership

Intricity authors a highly sought after Data Management Video Series targeted towards Business Stakeholders at https://www.intricity.com/videos. These videos are used in universities across the world. Here is a small set of universities leveraging Intricity’s videos as a teaching tool:

Talk With a Specialist

If you would like to talk with an Intricity Specialist about your particular scenario, don’t hesitate to reach out to us. You can write us an email: specialist@intricity.com

(C) 2023 by Intricity, LLC

This content is the sole property of Intricity LLC. No reproduction can be made without Intricity's explicit consent.

Intricity, LLC. 244 Fifth Avenue Suite 2026 New York, NY 10001

Phone: 212.461.1100 • Fax: 212.461.1110 • Website: www.intricity.com