In a way, you could say that every company is a manufacturing company. There's always a "raw material" or something in need of improvement, a value-added process, and an emergent product or result of value. This is why manufacturing assessment frameworks like SIPOC work so well for evaluating any process.

The "factory" of your organization has to be proficient at manufacturing two things:

- Whatever your customers pay you for

- Turning data into information

That second item might sound self-serving and maybe it is. But step back and think of the things your organization actually "manufactures". If you're a services organization, you manufacture an improvement of some sort and it has a process. You need to be good at that process.

How do you know you're good at that process? Sure if you're a lone electrician, you can easily decide whether a job was well done, but how do you evaluate an army of electricians? The only way of actually "seeing" those electricians is through data. However, raw data is noisy and easily misinterpreted by various parties. So data must be treated strategically for an organization to "see" itself. Thus turning data into information must be taken on as an adopted manufacturing process that the organization must own. There's no pixie dust for this process and no "easy button", but there is a way to do it right to reduce waste. To do so you must start from a very strategic vantage point.

Strategic Superorganism

Ants, termites, bees, and dolphin pods act like superorganisms when they take on roles and accomplish something greater than the sum of their parts. Companies behave like superorganisms too. To get an organization to operate like a superorganism for a new process requires a strategy with business and technical stakeholders. This ensures that the end product of that "manufacturing process" provides the expected value. Then a detailed plan for standing up the "factory" has to be defined with all its pieces and parts.

Ants, termites, bees, and dolphin pods act like superorganisms when they take on roles and accomplish something greater than the sum of their parts. Companies behave like superorganisms too. To get an organization to operate like a superorganism for a new process requires a strategy with business and technical stakeholders. This ensures that the end product of that "manufacturing process" provides the expected value. Then a detailed plan for standing up the "factory" has to be defined with all its pieces and parts.

Executive Alignment

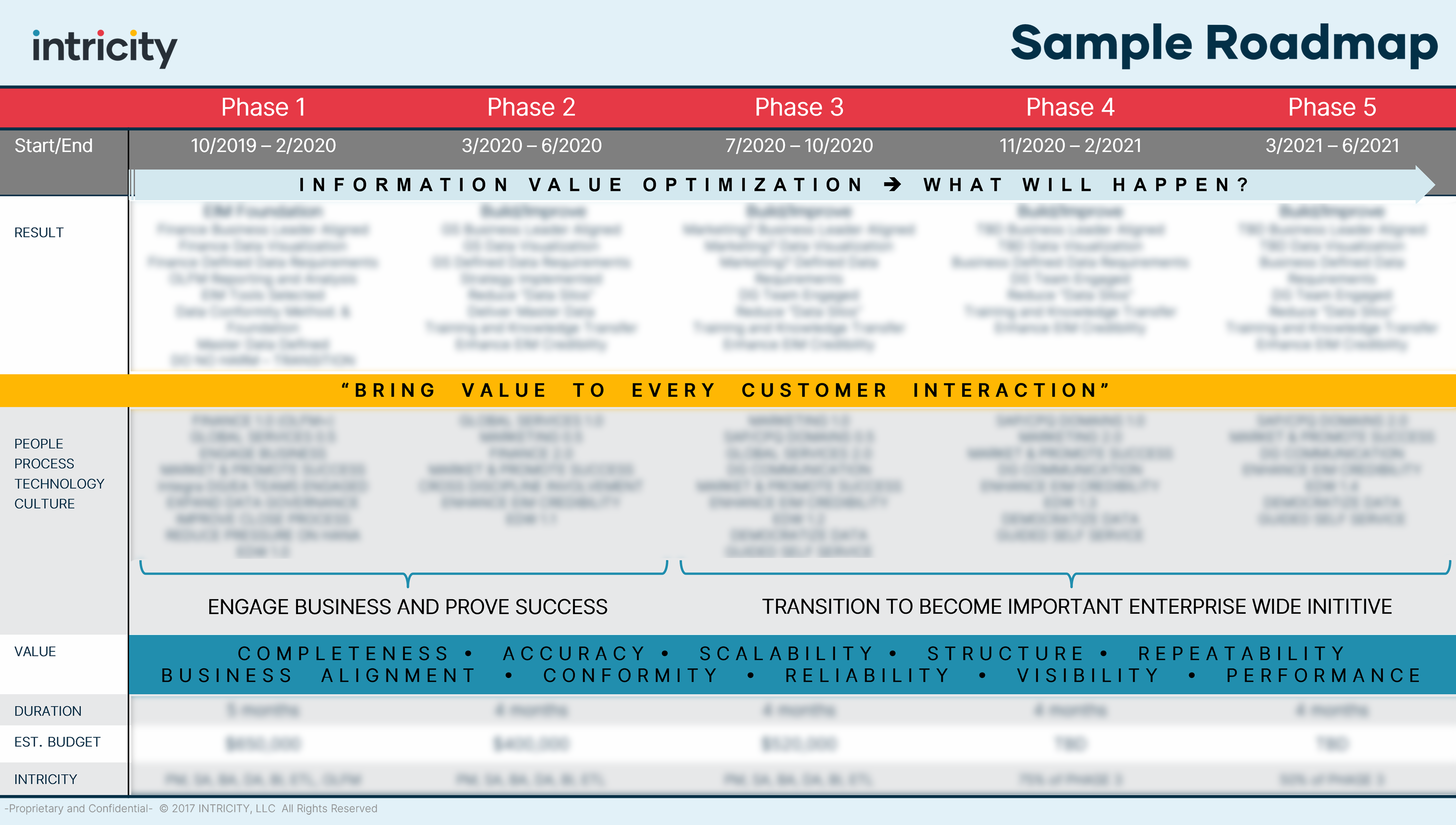

There are two strategic deliverables that can help set the stage for this plan. The first is a strategic roadmap. This deliverable provides an executive perspective on standing up that factory. How much it costs, who is involved, what phases are required, what objective it meets, the tie to the corporate mission, and the duration to its attainment. Without giving too much away, here is a blurred version of what one of these strategic roadmaps provides:

Project Member Alignment (Post Funding)

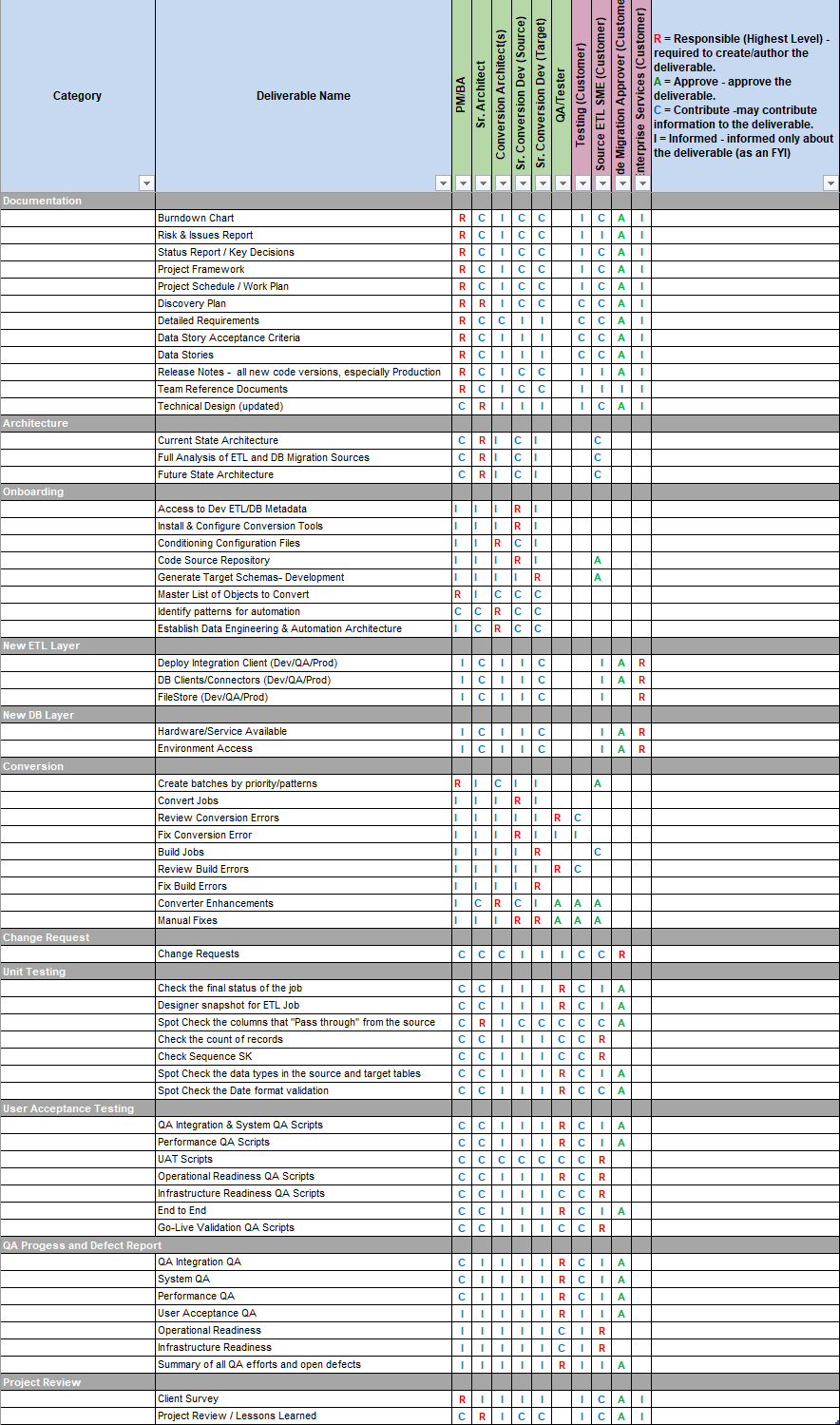

Beyond the Executive Alignment, to obtain superorganism status, the project team members must also be aligned. Obtaining this alignment can occur once the project has approved funding. This alignment breaks down the processes needing completion by members of the project teams. This matrix provides a clear depiction of everybody's role in relation to the task being completed. The tracking of this is done in what is called a RACI matrix. This is a sample matrix for a sample code conversion project. Each process step indicates whether the person is Responsible, Approves deliverables, Contributes, or is Informed:

Outcome

While setting up a data-to-information factory takes time and work, this is one of the things that every organization must be proficient in doing. Even though organizations don't necessarily have to be experts on how the factory is constructed, they do need to operate the factory once it is in place. For this reason, when Intricity builds out these factories within organizations, the teams are often mixed. This provides a natural knowledge transfer so sustaining the flow of data to information is understood. Additionally, the transition of how to assemble new subject matters goes from high Intricity involvement in the first subject matter, to lower and lower in the latter subject matters. In the end, the organization is able to say it's good at two things:

- Whatever their customer pay them for

- Turning data into information

Who is Intricity?

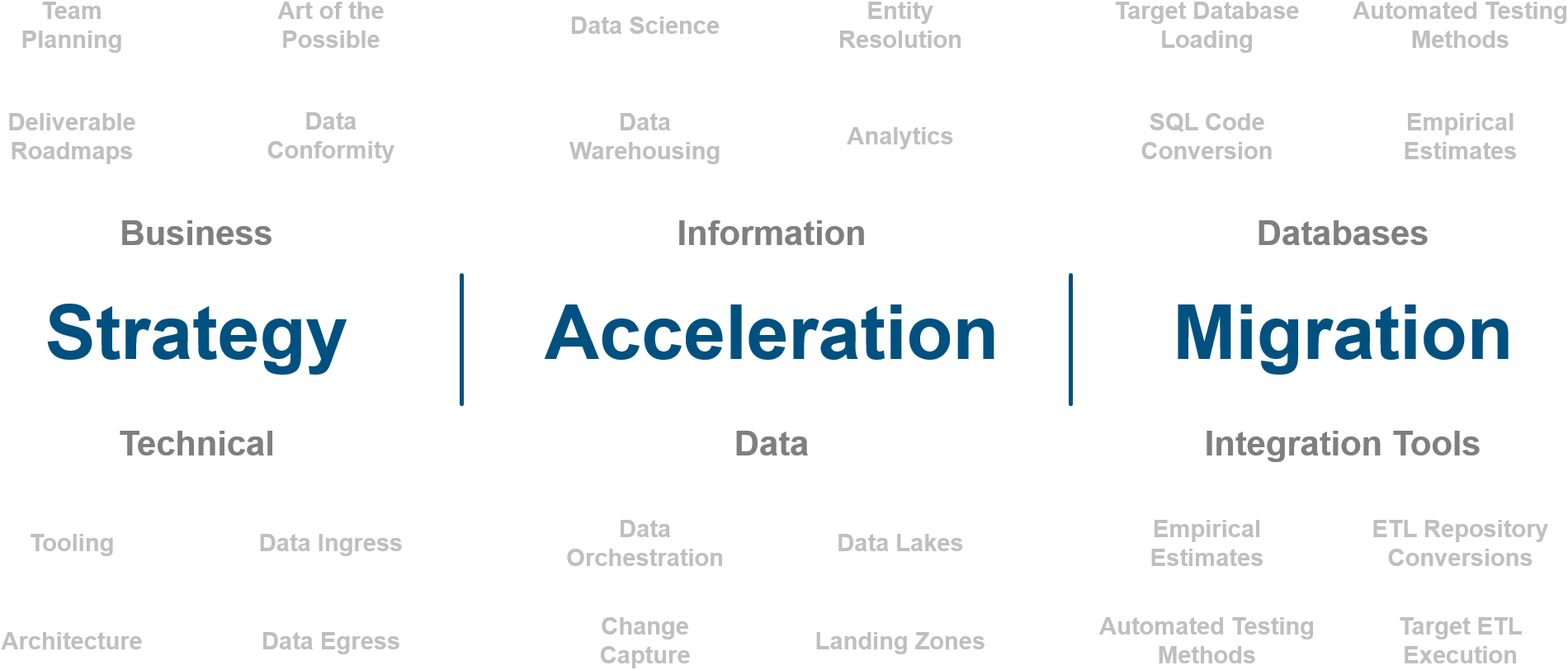

Intricity is a specialized selection of over 100 Data Management Professionals, with offices located across the USA and Headquarters in New York City. Our team of experts has implemented in a variety of Industries including, Healthcare, Insurance, Manufacturing, Financial Services, Media, Pharmaceutical, Retail, and others. Intricity is uniquely positioned as a partner to the business that deeply understands what makes the data tick. This joint knowledge and acumen has positioned Intricity to beat out its Big 4 competitors time and time again. Intricity’s area of expertise spans the entirety of the information lifecycle. This means when you’re problem involves data; Intricity will be a trusted partner. Intricity's services cover a broad range of data-to-information engineering needs:

What Makes Intricity Different?

While Intricity conducts highly intricate and complex data management projects, Intricity is first a foremost a Business User Centric consulting company. Our internal slogan is to Simplify Complexity. This means that we take complex data management challenges and not only make them understandable to the business but also make them easier to operate. Intricity does this through using tools and techniques that are familiar to business people but adapted for IT content.

Thought Leadership

Intricity authors a highly sought after Data Management Video Series targeted towards Business Stakeholders at https://www.intricity.com/videos. These videos are used in universities across the world. Here is a small set of universities leveraging Intricity’s videos as a teaching tool:

Talk With a Specialist

If you would like to talk with an Intricity Specialist about your particular scenario, don’t hesitate to reach out to us. You can write us an email: specialist@intricity.com

(C) 2023 by Intricity, LLC

This content is the sole property of Intricity LLC. No reproduction can be made without Intricity's explicit consent.

Intricity, LLC. 244 Fifth Avenue Suite 2026 New York, NY 10001

Phone: 212.461.1100 • Fax: 212.461.1110 • Website: www.intricity.com